Temperature: We precisely manage the air’s moisture to stop the produce from drying out and to keep it firm.

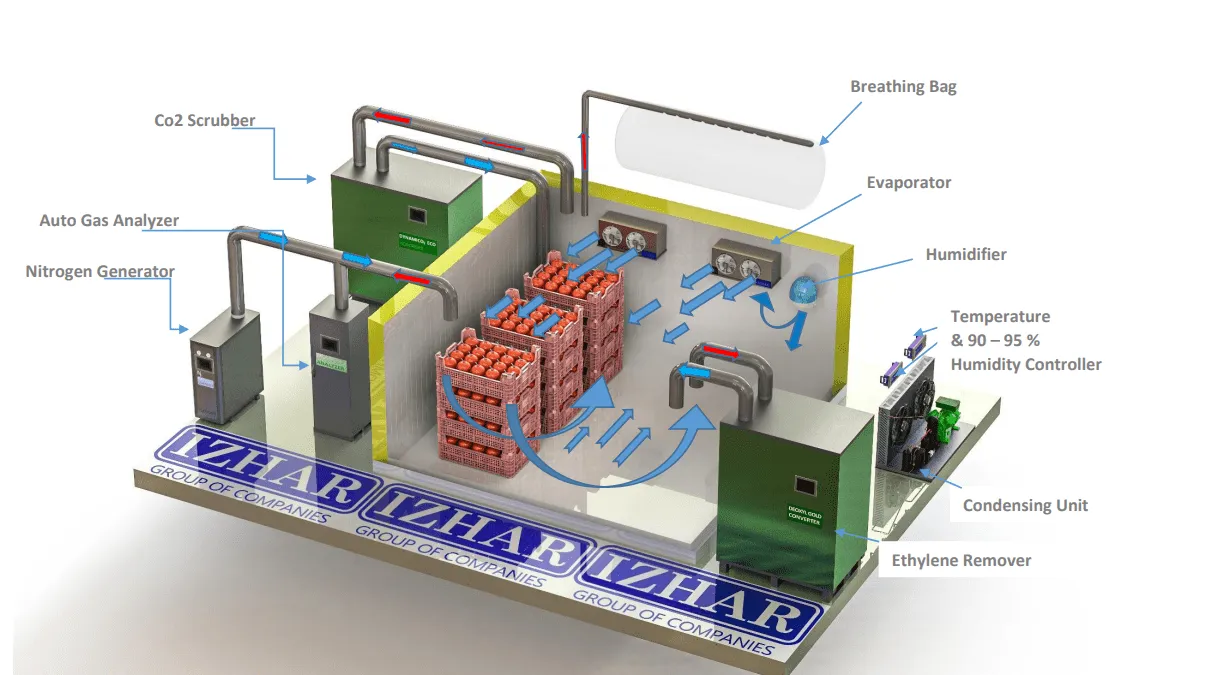

By precisely controlling these gas levels, we create an optimal environment that slows down the natural respiration and metabolic processes of fresh produce – delaying ripening, reducing spoilage and significantly extending shelf life, quality, and freshness.

The following are some benefits of using Controlled Atmosphere Stores:

Choosing Izhar Foster for your Controlled Atmosphere storage needs means partnering with a team dedicated to preserving the value of your harvest. Here’s what sets us apart:

To explore how Controlled Atmosphere storage can benefit your produce, contact Izhar Foster for a professional consultation today.